Abrasive waterjet is a controlled erosion cutting process using high pressure water mixed with an abrasive (crushed garnet) to cut almost any type of material.

Abrasive waterjet is a controlled erosion cutting process using high pressure water mixed with an abrasive (crushed garnet) to cut almost any type of material.

Capabilities

The use of waterjet processing can offer significant opportunity to increase productivity and lower total production costs.

- Cut any simple or complex 2D shape in most materials up to 6″ thick.

- Table cutting capacity of 24″ x 48″ and 48″ x 96″.

- Tolerance capability to +/- .005 repeatability +/- .002. Actual tolerance may vary depending on part configuration, material grade and thickness.

- Will cut virtually any material, including heat sensitive materials such as stainless steel, nickel and titanium.

Advantages

- Waterjet cutting can eliminate many standard machining processes resulting in reduced cycle time, increased throughput and lower parts costs.

- Saves money by eliminating secondary operations.

- Small kerf (.030″) will improve material utilization

- No heat-affected zones or structural changes. Finishing if necessary will remove the base material instead of hard heat-affected material.

- Ease of setup can accommodate small or large quantities.

- Omni directional shape cutting will allow tight angles and sharp corners.

- Waterjet cutting often eliminates the need for deburring depending on the type of material.

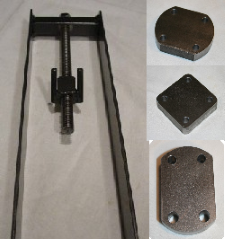

Some of the materials for waterjet cutting

- Wood – Phenolic – Aluminum – Copper – Fiberglass – Plastic – Glass (non-tempered) – Lexan – Rubber – Nylon – Plexiglass – Foam – Urethane – Concrete – Polypropylene – Marble – Brass – Steel (all types) – Zincalloy – Titanium – Tool Steel

Read Our Testimonials

Read Our Testimonials